Q8(b) Analyse the spatial changes and emerging patterns of semiconductor manufacturing in the world. 15 Marks (PYQ/2024)

Answer:

Introduction

Semiconductor manufacturing has undergone significant spatial transformation over the past two decades. Traditionally concentrated in East Asia—particularly in Taiwan, South Korea, and Japan—the industry is now experiencing a geographic reconfiguration. This change is driven by factors such as the explosive demand for advanced chips (particularly for AI, 5G, and electric vehicles), geopolitical tensions, and strategic policy interventions like the U.S. CHIPS Act. The emerging patterns reflect a shift from a singular concentration of high-tech manufacturing to a more fragmented, regionally diversified supply chain that balances risk, cost, and resilience.

1. Theoretical Perspectives and Models

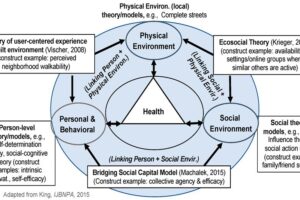

Semiconductor manufacturing’s spatial evolution can be understood through several theoretical lenses:

1.1 Weber’s Industrial Location Theory

Alfred Weber’s theory emphasizes three key factors influencing industrial location:

- Transportation Costs: Industries tend to locate near raw material sources if transportation costs are high.

- Labor Costs: If labor is cheaper in a particular region, industries may relocate.

- Agglomeration Economies: Firms benefit from clustering due to shared infrastructure and knowledge spillovers.

In semiconductor manufacturing, firms historically clustered in East Asia due to cost advantages and skilled labor availability. However, rising geopolitical risks and supply chain vulnerabilities are prompting diversification.

1.2 Porter’s Cluster Theory

Clusters are geographic concentrations of interconnected companies and institutions in a particular field. Historic clusters like Taiwan’s Hsinchu Science Park illustrate how semiconductor firms reap agglomeration benefits. However, as global risks mount, firms are seeking to diversify beyond these traditional hubs.

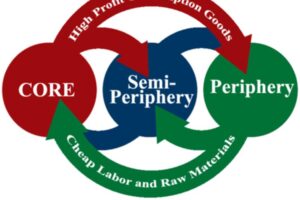

1.3 New Economic Geography (Krugman)

This framework explains how economies of scale, transportation costs, and market access determine spatial agglomeration. The high concentration of advanced nodes (sub-22nm technology) in regions like Taiwan and the U.S. is increasingly balanced by the need to establish decentralized production for mature nodes in China, Southeast Asia, and even parts of Europe.

1.4 Global Value Chain Analysis

As supply chains become more fragmented due to trade disputes and national security concerns, the semiconductor sector exemplifies the trend toward regionalization. High-value processes such as chip design and advanced node manufacturing remain clustered in key regions, while assembly and testing relocate to new nodes to lower costs and mitigate risk.

1.5 Diffusion of Information

The rapid spread of technological knowledge and expertise has enabled semiconductor firms to establish production facilities in new regions. Countries investing in semiconductor education and R&D are emerging as new players in the industry.

1.6 Delocalization of Semiconductor Industries

Delocalization refers to the shift of industries from traditional hubs to new regions due to cost, policy, and risk factors. Semiconductor firms are increasingly setting up fabs in the U.S., Europe, and Southeast Asia to reduce dependency on East Asia.

2. Key Drivers of Spatial Change

Recent years have witnessed an unprecedented expansion in transnational engagement due to:

2.1 Technological Demand and Specialization

- Surging demand from AI, 5G, and EV industries is driving capacity expansion, particularly in advanced semiconductor nodes.

- Specialized roles have emerged. For example, Taiwan and the U.S. continue to dominate advanced nodes, while China concentrates on mature nodes, leading to a bifurcated spatial pattern within the industry.

2.2 Geopolitical Pressures and Policy Interventions

- Rising geopolitical tensions—especially between the U.S. and China—have spurred national policies to re-shore production.

- The U.S. CHIPS Act and similar European initiatives are promoting domestic fabs to secure supply.

2.3 Supply Chain Resilience and Diversification

- The trade-offs between cost, capacity, and risk have led firms to diversify their geographic footprint.

- Global capital expenditure in semiconductors is approaching $1 trillion through 2030, with investments aimed at mitigating disruptions and enhancing regional supply chain security.

3. Case Studies

3.1 Taiwan’s Hsinchu Science Park

Historically the heart of semiconductor innovation, Taiwan’s Hsinchu Science Park has underpinned global leadership in advanced chip fabrication. However, geopolitical tensions (e.g., U.S.–China rivalry) are prompting companies headquartered in Taiwan to seek geographic diversification.

3.2 The U.S. Semiconductor Renaissance

In response to the CHIPS Act, several major U.S. companies—such as Intel and GlobalFoundries—have initiated large-scale investments to build advanced fabs in states like Arizona and Texas.

Conclusion

The spatial changes in semiconductor manufacturing are the product of a complex interplay between technological demand, geopolitical factors, and strategic policy interventions. While traditional clusters still dominate high-end production, a global realignment is underway—a shift toward greater geographic diversification and risk management. By integrating insights from Weber’s industrial location theory, diffusion of information, and delocalization trends, we can better understand how these emerging patterns are reshaping the semiconductor landscape in an era defined by rapid technological innovation and strategic competition.